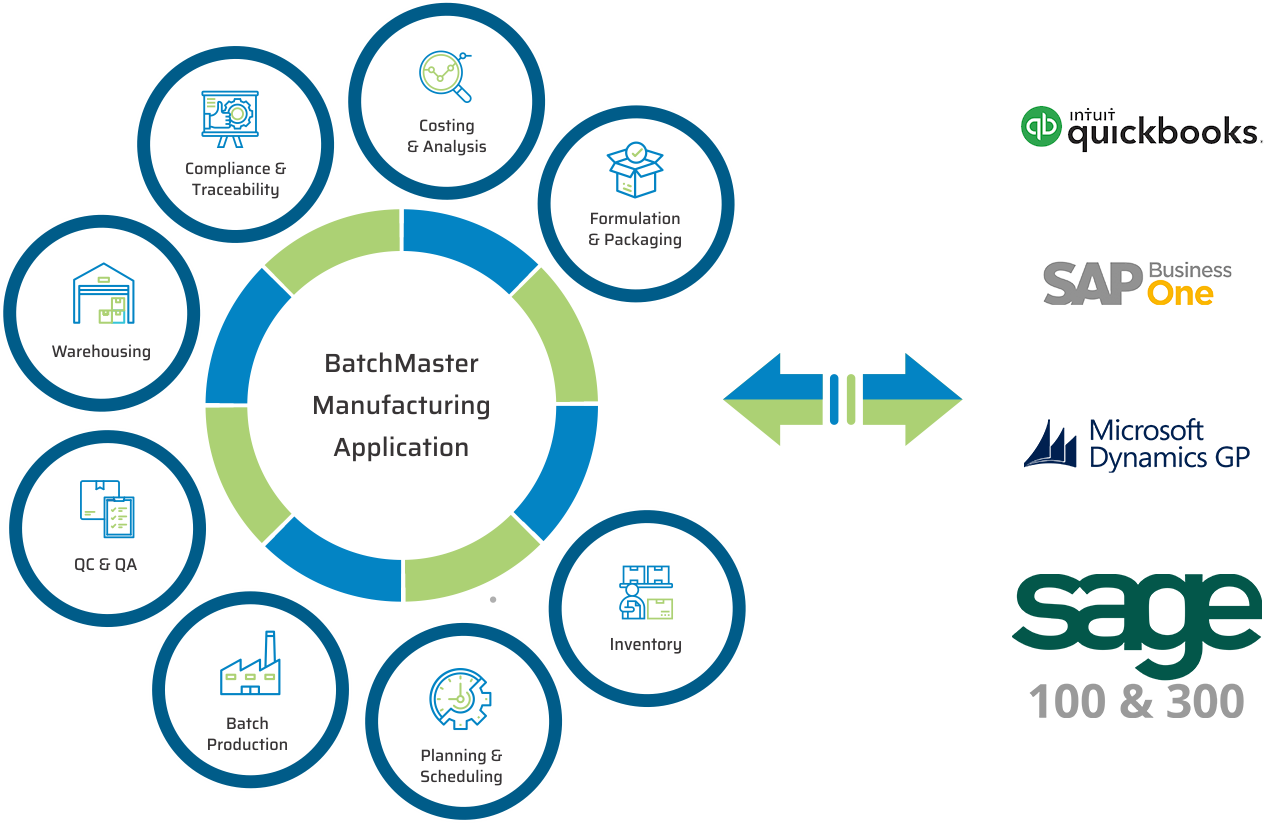

SAP Business One and BatchMaster Software

- Inventory management

- Traceability

- Quality control

- Production management

- Formulation

- Industry specific compliance

- Planning & Scheduling

BatchMaster ERP for Food & Beverages

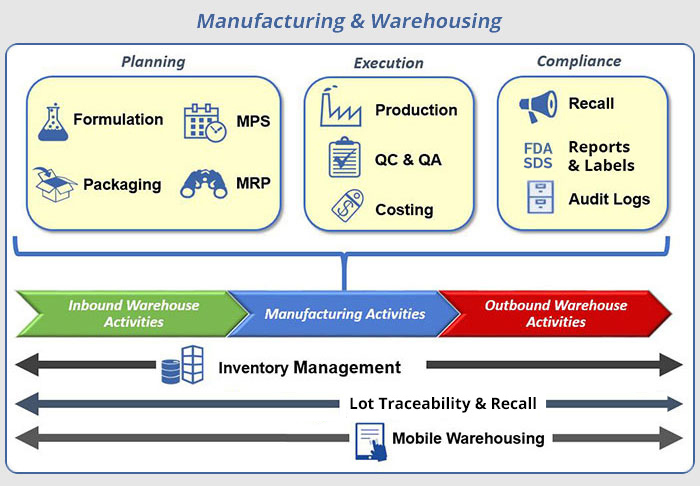

BatchMaster Software offers a fully integrated ERP suite that handles all aspects of your growing Food & Beverages business from sales and purchasing to manufacturing and distribution.

As an OEM SAP partner, BatchMaster Software has configured the SAP Business One application to meet the needs of growing SMB Food & Beverages manufacturers by embedding BatchMaster‘s Food & Beverages modules within the Business One framework, and enhancing Business One’s menu structures, collaboration tools, inquiries and reports. The resulting solution, BatchMaster ERP for Food, is affordable, quick to deploy as an on-premise or cloud solution, and easy to maintain.

Our product has certified integration with SAP Business One.

Complete Food & Beverages ERP Solution

Whether you private-label, co-pack or produce your own line of Food & Beverages products, BatchMaster ERP for Food & Beverages offers your staff all the time-saving tools and real-time actionable data they need in these areas:

The Power of One ERP System

One User Login

Accesses all transactions'Private Cloud' environment.

One User Interface

Easy to learn and use

One Database

Instant access to accurate data

Food & Beverages Processing Software That Will Change the Way You Work

- Inventory

- Traceability

- Quality

- Production

- Formulation

- Compliance

- Planning & Scheduling

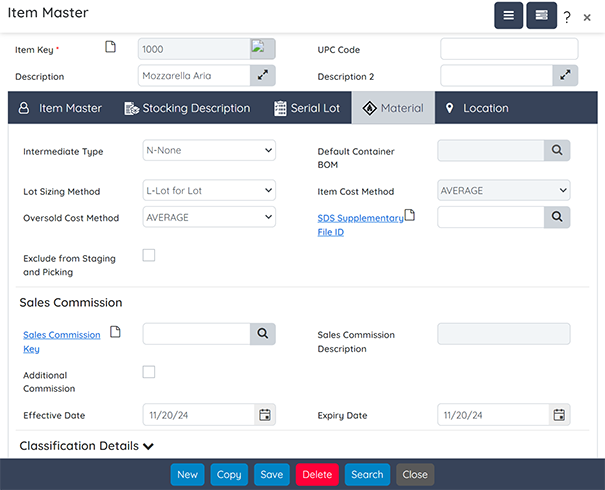

Inventory

Key features include:

- Attribute Management: Maintain records for allergens, safety, certifications, and industry-specific documents.

- Smart Allocation: Allocate inventory based on expiry dates and quality status.

- Batch Adjustments: Dynamically adjust batch jobs according to inventory characteristics.

- Mobile Warehousing: Execute warehousing tasks efficiently using mobile devices.

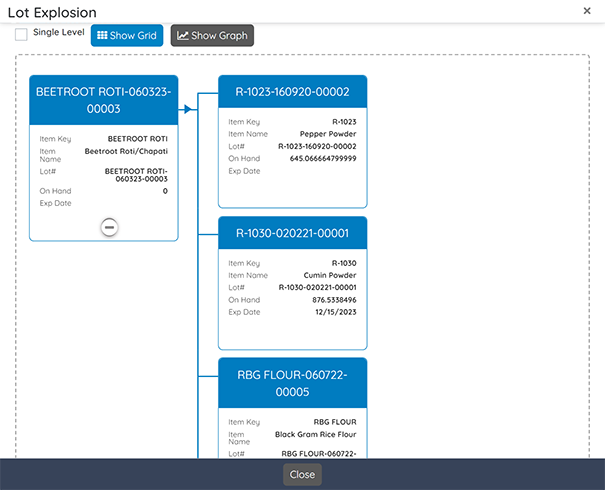

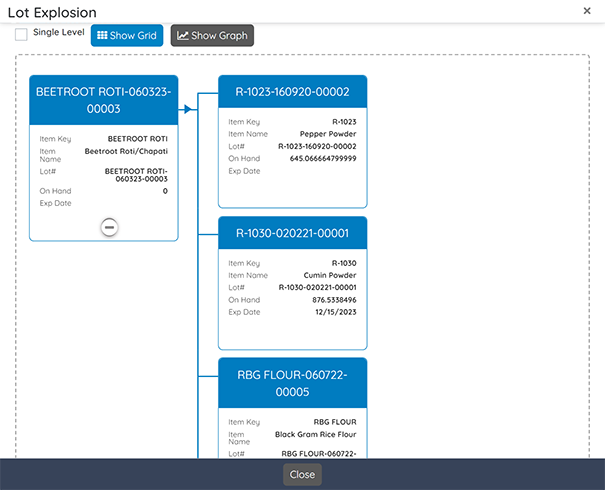

Traceability

Key features include:

- Automatic Lot Numbering: Assign lot numbers automatically during receiving and production.

- Lifecycle Tracking: Capture and validate lot numbers at every stage of production.

- Quick Searches: Perform bi-directional searches using an intuitive graphical tool.

- Recall Management: Generate barcoded labels (e.g., product labels, pallet licenses) to further streamline operations.

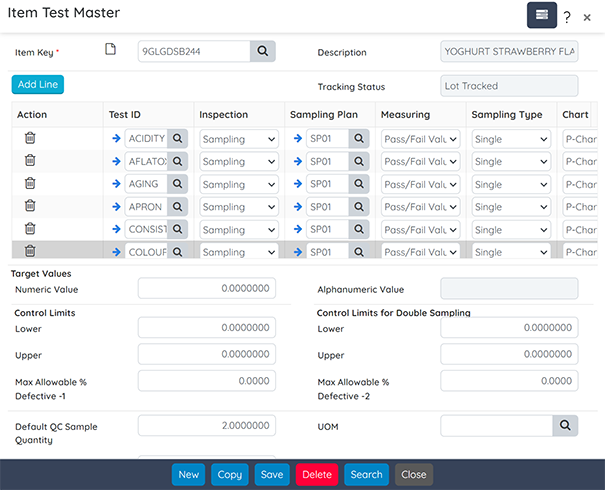

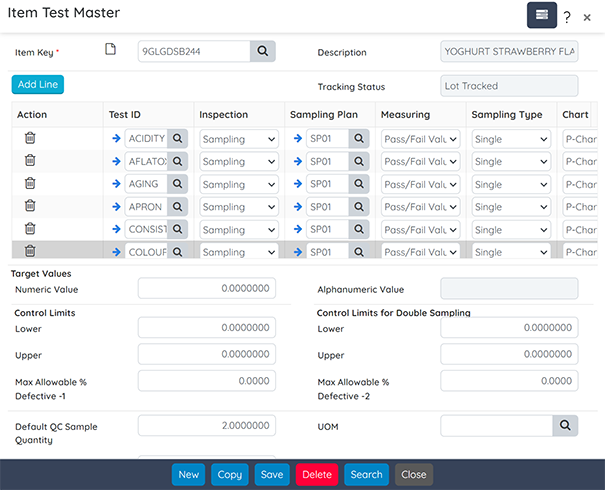

Quality

Integrate quality control and assurance throughout all processes, ensuring product safety and compliance.

Key features include:

- QC Testing: Set up quality control tests with specified tolerance and sample values.

- Inspection Plans: Execute comprehensive inspection plans and checklists.

- Documentation: Generate Certificates of Analysis (COA) and manage production deviations.

- Issue Management: Address customer complaints and nonconformance situations effectively.

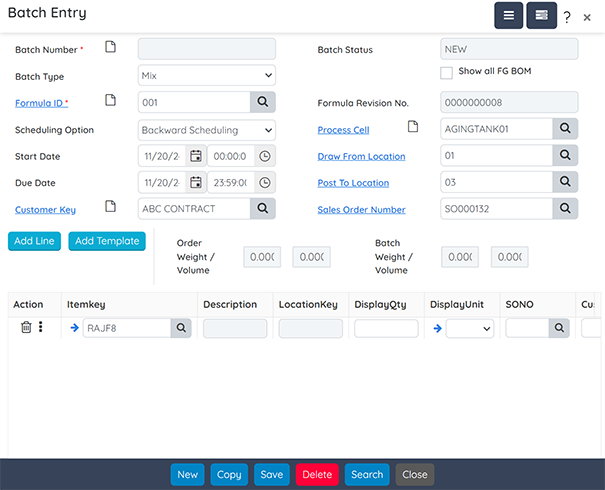

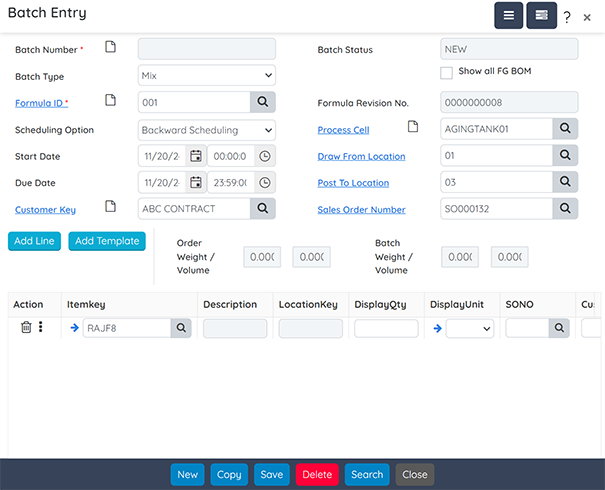

Production

Optimize production processes for intermediates and finished goods, including co-products and by-products.

Key capabilities include:

- Dynamic Job Scheduling: Link and schedule dependent batch jobs based on resource availability.

- Resource Management: Manage equipment capacities and resource allocations efficiently.

- Deviation Capture: Record and address deviations during production runs.

- Inventory Backflushing: Automatically backflush inventory for completed jobs.

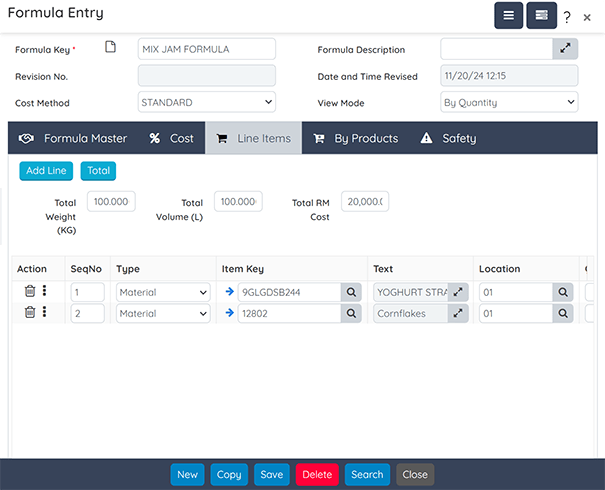

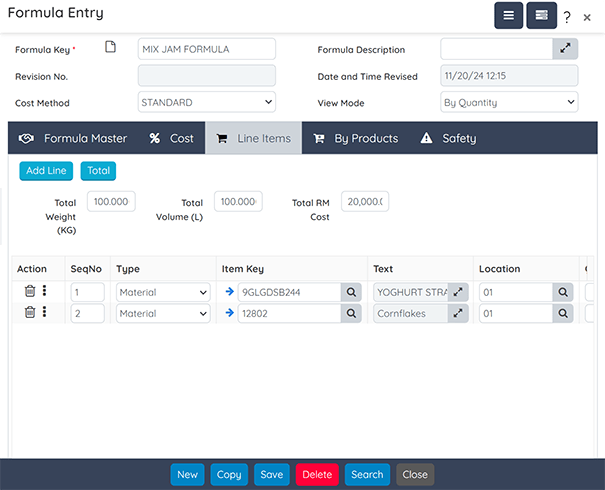

Formulation

Facilitate the management of product specifications across multiple versions and formulations.

Key features include:

- Dynamic Adjustments: Modify ingredient weights and volumes to achieve target properties.

- Cost Analysis: Account for fixed and variable labor and consumable costs.

- Specification Comparison: Analyze and compare different product specifications.

- Workflow Approval: Employ multi-level workflows for formulation approvals.

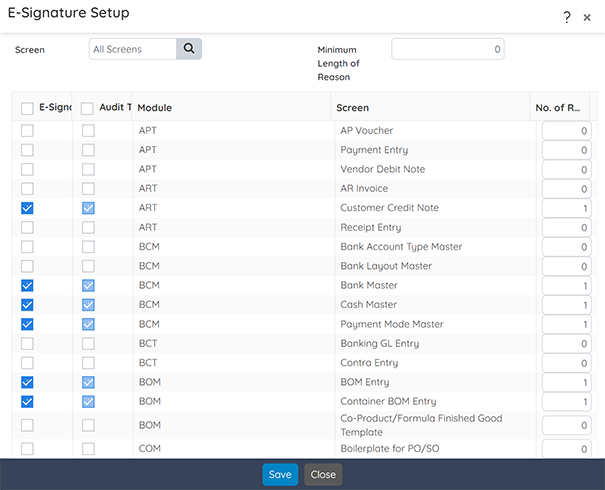

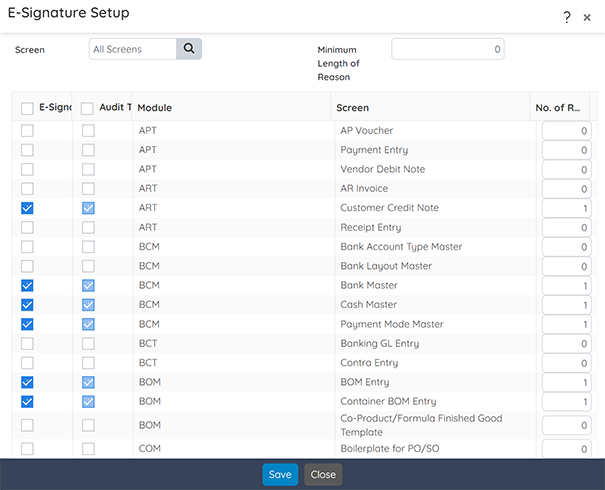

Compliance

Ensure adherence to federal and industry-specific regulations throughout every process.

Key functionalities include:

- Real-Time Alerts: Notify formulators when specifications exceed established levels.

- Data Capture: Mandate the collection of item, user, and location data for compliance (CFR 11).

- Audit Trail Maintenance: Maintain transactional history for auditor reporting, including Master Batch Records.

- Label Generation: Automatically generate required product and safety labels and documents.

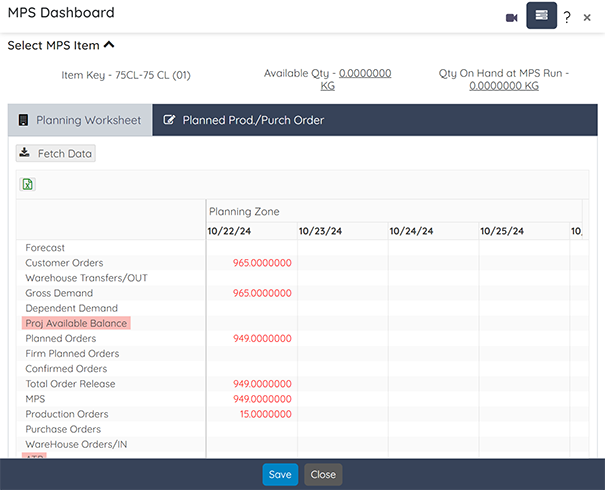

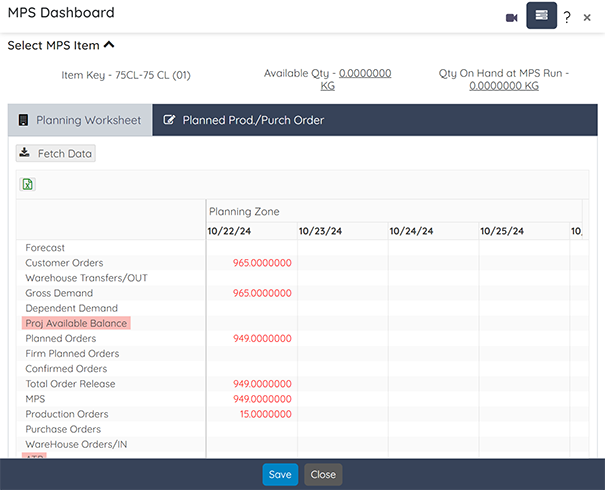

Planning & Scheduling

Optimize production and procurement processes to meet demand effectively.

Key capabilities include:

- Comprehensive Planning: Establish short, medium, and long-range planning periods.

- Facility Management: Plan production by facility or across multiple locations.

- Supply and Demand Consolidation: Streamline supply and demand management across facilities.

- What-If Analysis: Perform scenario analysis while planning production schedules.

Inventory

Key features include:

- Automatic Lot Numbering: Assign lot numbers automatically during receiving and production.

- Lifecycle Tracking: Capture and validate lot numbers at every stage of production.

- Quick Searches: Perform bi-directional searches using an intuitive graphical tool.

- Recall Management: Generate barcoded labels (e.g., product labels, pallet licenses) to further streamline operations.

Quality

Key features include:

- QC Testing: Set up quality control tests with specified tolerance and sample values.

- Inspection Plans: Execute comprehensive inspection plans and checklists.

- Documentation: Generate Certificates of Analysis (COA) and manage production deviations.

- Issue Management: Address customer complaints and nonconformance situations effectively.

Production

Key capabilities include:

- Dynamic Job Scheduling: Link and schedule dependent batch jobs based on resource availability.

- Resource Management: Manage equipment capacities and resource allocations efficiently.

- Deviation Capture: Record and address deviations during production runs.

- Inventory Backflushing: Automatically backflush inventory for completed jobs.

Formulation

Key features include:

- Dynamic Adjustments: Modify ingredient weights and volumes to achieve target properties.

- Cost Analysis: Account for fixed and variable labor and consumable costs.

- Specification Comparison: Analyze and compare different product specifications.

- Workflow Approval: Employ multi-level workflows for formulation approvals.

Compliance

Key functionalities include:

- Real-Time Alerts: Notify formulators when specifications exceed established levels.

- Data Capture: Mandate the collection of item, user, and location data for compliance (CFR 11).

- Audit Trail Maintenance: Maintain transactional history for auditor reporting, including Master Batch Records.

- Label Generation: Automatically generate required product and safety labels and documents.

Planning & Scheduling

Optimize production and procurement processes to meet demand effectively.

Key capabilities include:

- Comprehensive Planning: Establish short, medium, and long-range planning periods.

- Facility Management: Plan production by facility or across multiple locations.

- Supply and Demand Consolidation: Streamline supply and demand management across facilities.

- What-If Analysis: Perform scenario analysis while planning production schedules.

The BatchMaster Software Advantage

- SAP Certified Partner (OEM / VAR / SSP)

- 100% Focus on Process Manufacturing Solutions

- Over 30 Years Experience

- “Built from the Ground Up” Architecture

- Supports Food & Beverages Specific Requirements and Best Practices

- Delivered as Preconfigured “Out of the Box” Solution

- Offers Simple, Intuitive and Personalized Controls

- Easily Adaptable to Change