This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

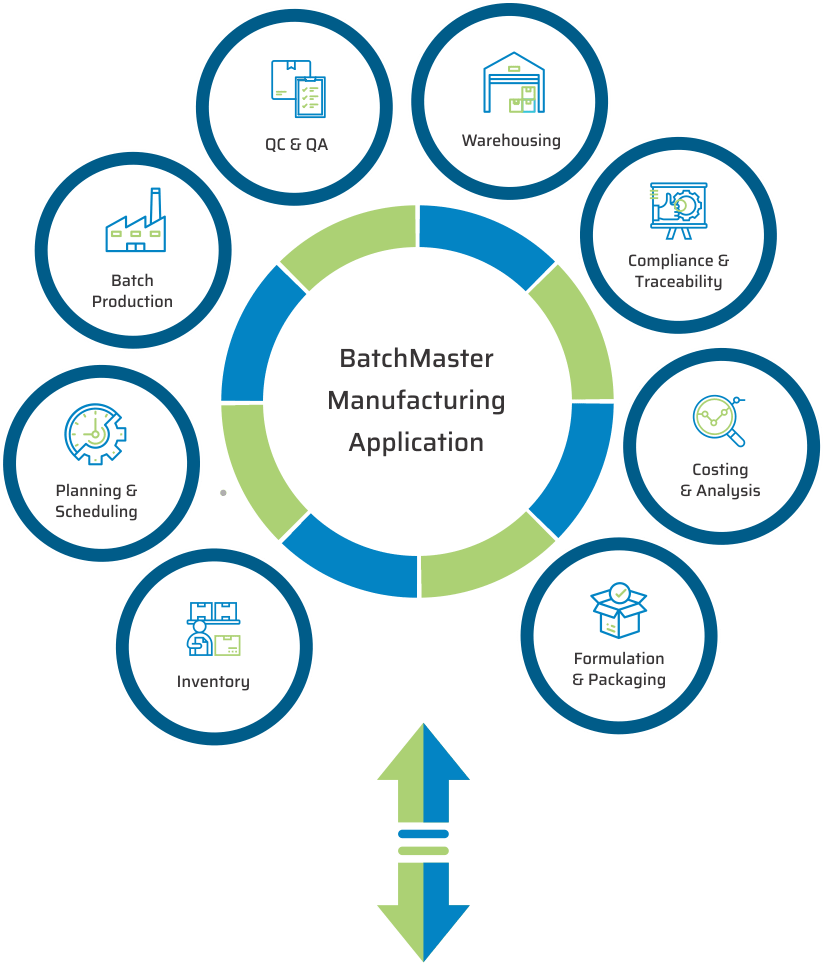

Leading Manufacturing ERP Software for the Food, Chemical, Nutraceutical and Life Sciences industries

- Inventory management

- Traceability

- Quality control

- Production management

- Formulation

- Industry specific compliance

- Planning & Scheduling

Food Processing Software That Will Change the Way You Work

- Inventory

- Traceability

- Quality

- Production

- Formulation

- Compliance

- Planning & Scheduling

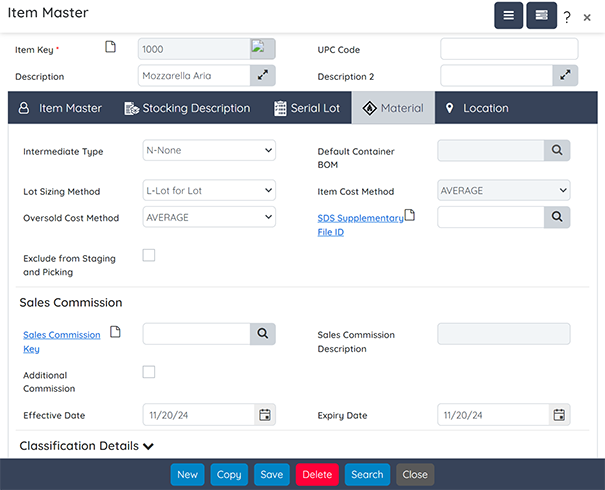

Inventory

Key features include:

- Attribute Management: Maintain records for allergens, safety, certifications, and industry-specific documents.

- Smart Allocation: Allocate inventory based on expiry dates and quality status.

- Batch Adjustments: Dynamically adjust batch jobs according to inventory characteristics.

- Mobile Warehousing: Execute warehousing tasks efficiently using mobile devices.

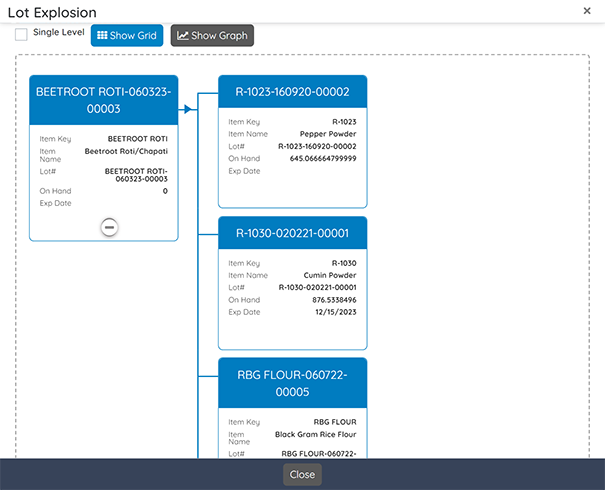

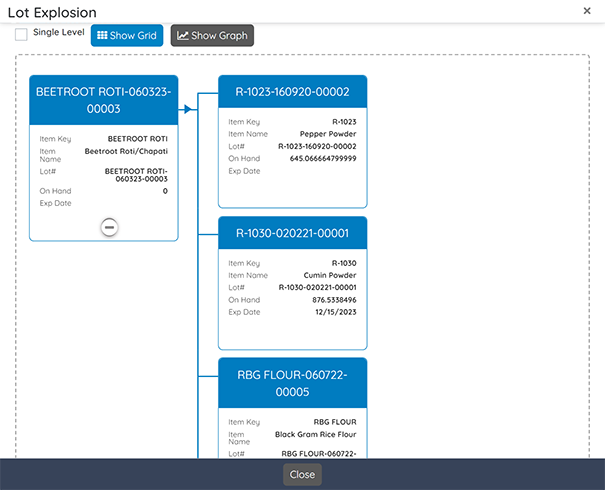

Traceability

Key features include:

- Automatic Lot Numbering: Assign lot numbers automatically during receiving and production.

- Lifecycle Tracking: Capture and validate lot numbers at every stage of production.

- Quick Searches: Perform bi-directional searches using an intuitive graphical tool.

- Recall Management: Generate barcoded labels (e.g., product labels, pallet licenses) to further streamline operations.

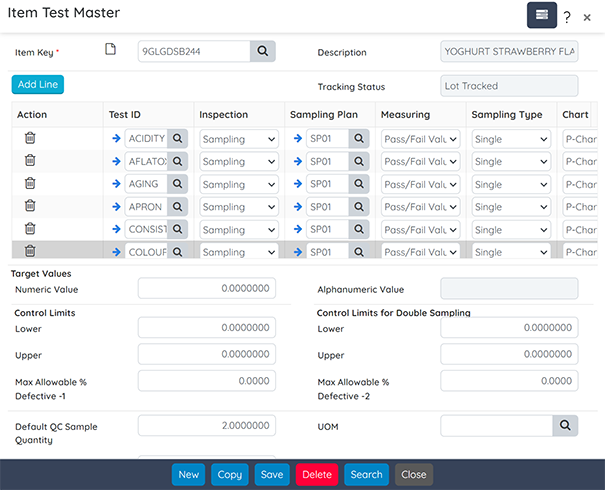

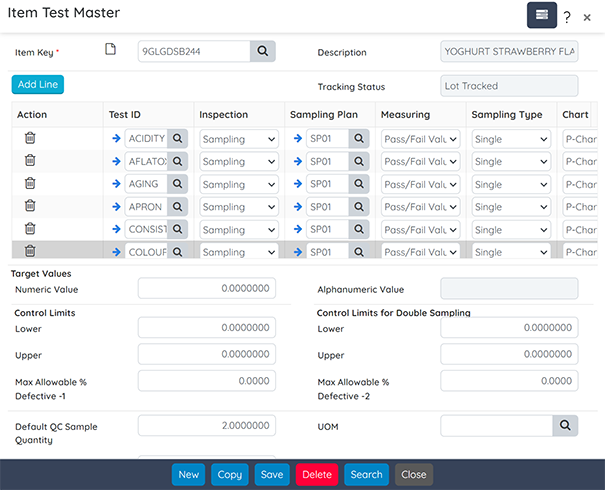

Quality

Integrate quality control and assurance throughout all processes, ensuring product safety and compliance.

Key features include:

- QC Testing: Set up quality control tests with specified tolerance and sample values.

- Inspection Plans: Execute comprehensive inspection plans and checklists.

- Documentation: Generate Certificates of Analysis (COA) and manage production deviations.

- Issue Management: Address customer complaints and nonconformance situations effectively.

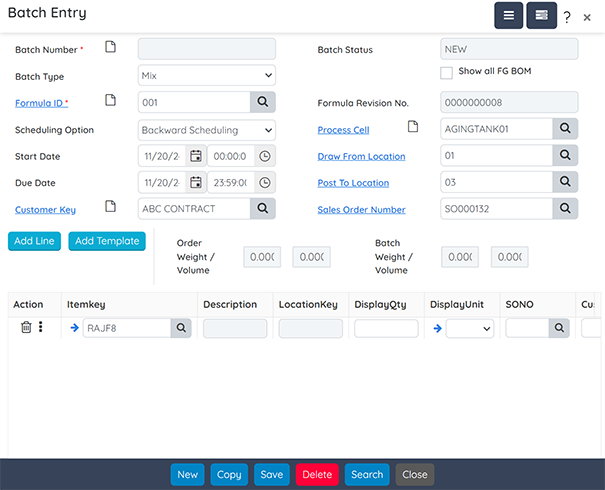

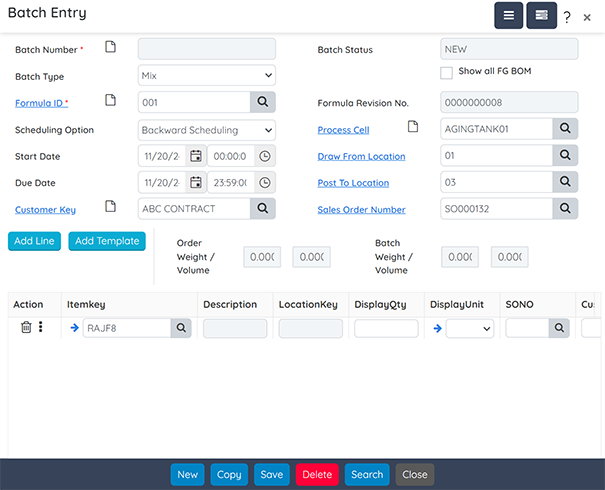

Production

Optimize production processes for intermediates and finished goods, including co-products and by-products.

Key capabilities include:

- Dynamic Job Scheduling: Link and schedule dependent batch jobs based on resource availability.

- Resource Management: Manage equipment capacities and resource allocations efficiently.

- Deviation Capture: Record and address deviations during production runs.

- Inventory Backflushing: Automatically backflush inventory for completed jobs.

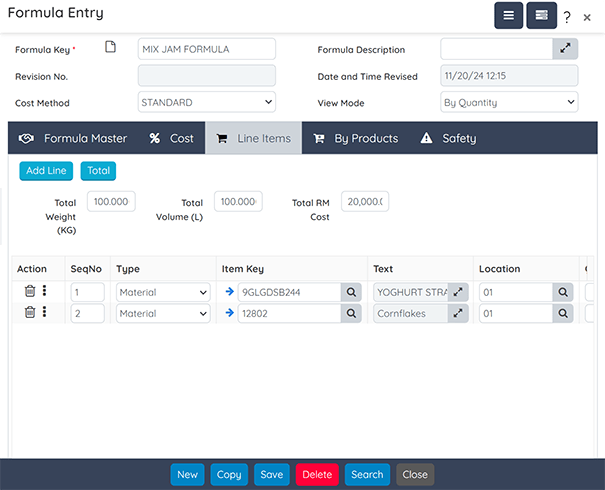

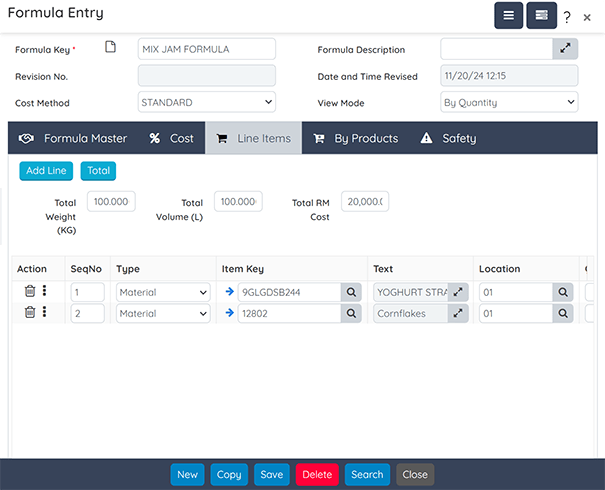

Formulation

Facilitate the management of product specifications across multiple versions and formulations.

Key features include:

- Dynamic Adjustments: Modify ingredient weights and volumes to achieve target properties.

- Cost Analysis: Account for fixed and variable labor and consumable costs.

- Specification Comparison: Analyze and compare different product specifications.

- Workflow Approval: Employ multi-level workflows for formulation approvals.

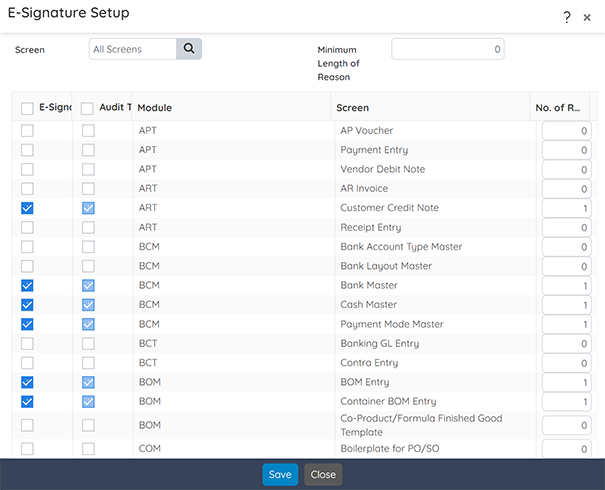

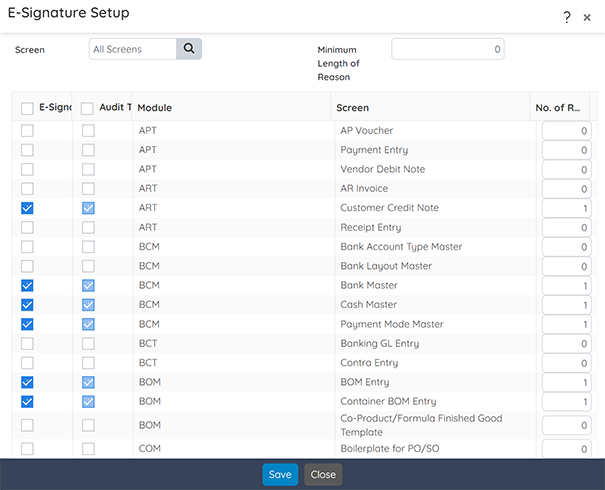

Compliance

Ensure adherence to federal and industry-specific regulations throughout every process.

Key functionalities include:

- Real-Time Alerts: Notify formulators when specifications exceed established levels.

- Data Capture: Mandate the collection of item, user, and location data for compliance (CFR 11).

- Audit Trail Maintenance: Maintain transactional history for auditor reporting, including Master Batch Records.

- Label Generation: Automatically generate required product and safety labels and documents.

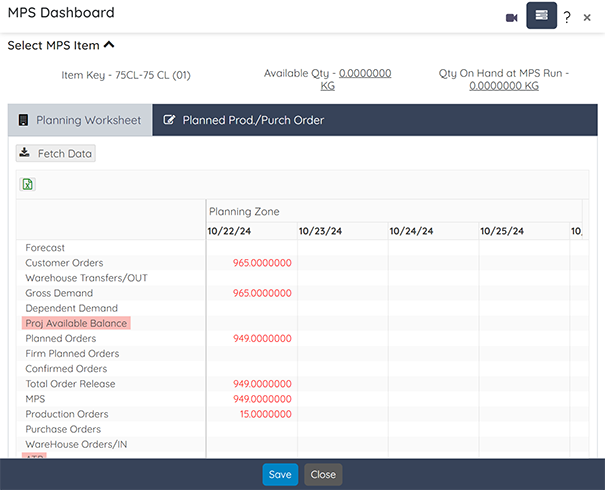

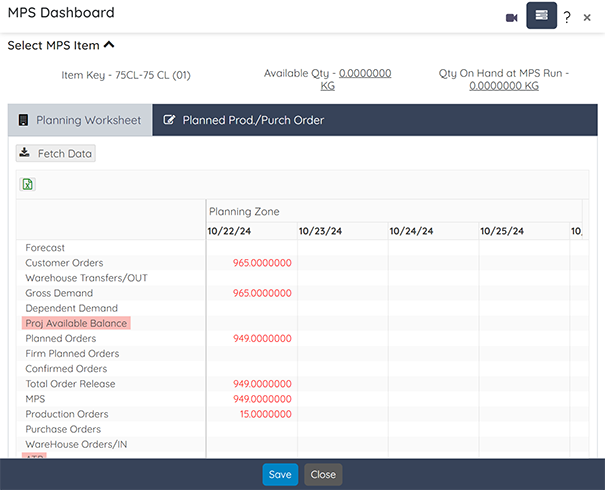

Planning & Scheduling

Optimize production and procurement processes to meet demand effectively.

Key capabilities include:

- Comprehensive Planning: Establish short, medium, and long-range planning periods.

- Facility Management: Plan production by facility or across multiple locations.

- Supply and Demand Consolidation: Streamline supply and demand management across facilities.

- What-If Analysis: Perform scenario analysis while planning production schedules.

Inventory

Key features include:

- Automatic Lot Numbering: Assign lot numbers automatically during receiving and production.

- Lifecycle Tracking: Capture and validate lot numbers at every stage of production.

- Quick Searches: Perform bi-directional searches using an intuitive graphical tool.

- Recall Management: Generate barcoded labels (e.g., product labels, pallet licenses) to further streamline operations.

Quality

Key features include:

- QC Testing: Set up quality control tests with specified tolerance and sample values.

- Inspection Plans: Execute comprehensive inspection plans and checklists.

- Documentation: Generate Certificates of Analysis (COA) and manage production deviations.

- Issue Management: Address customer complaints and nonconformance situations effectively.

Production

Key capabilities include:

- Dynamic Job Scheduling: Link and schedule dependent batch jobs based on resource availability.

- Resource Management: Manage equipment capacities and resource allocations efficiently.

- Deviation Capture: Record and address deviations during production runs.

- Inventory Backflushing: Automatically backflush inventory for completed jobs.

Formulation

Key features include:

- Dynamic Adjustments: Modify ingredient weights and volumes to achieve target properties.

- Cost Analysis: Account for fixed and variable labor and consumable costs.

- Specification Comparison: Analyze and compare different product specifications.

- Workflow Approval: Employ multi-level workflows for formulation approvals.

Compliance

Key functionalities include:

- Real-Time Alerts: Notify formulators when specifications exceed established levels.

- Data Capture: Mandate the collection of item, user, and location data for compliance (CFR 11).

- Audit Trail Maintenance: Maintain transactional history for auditor reporting, including Master Batch Records.

- Label Generation: Automatically generate required product and safety labels and documents.

Planning & Scheduling

Optimize production and procurement processes to meet demand effectively.

Key capabilities include:

- Comprehensive Planning: Establish short, medium, and long-range planning periods.

- Facility Management: Plan production by facility or across multiple locations.

- Supply and Demand Consolidation: Streamline supply and demand management across facilities.

- What-If Analysis: Perform scenario analysis while planning production schedules.

HELPING YOU MAINTAIN OUR LIFESTYLES AND SURROUNDINGS

Industry Specific Manufacturing Solutions

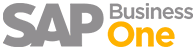

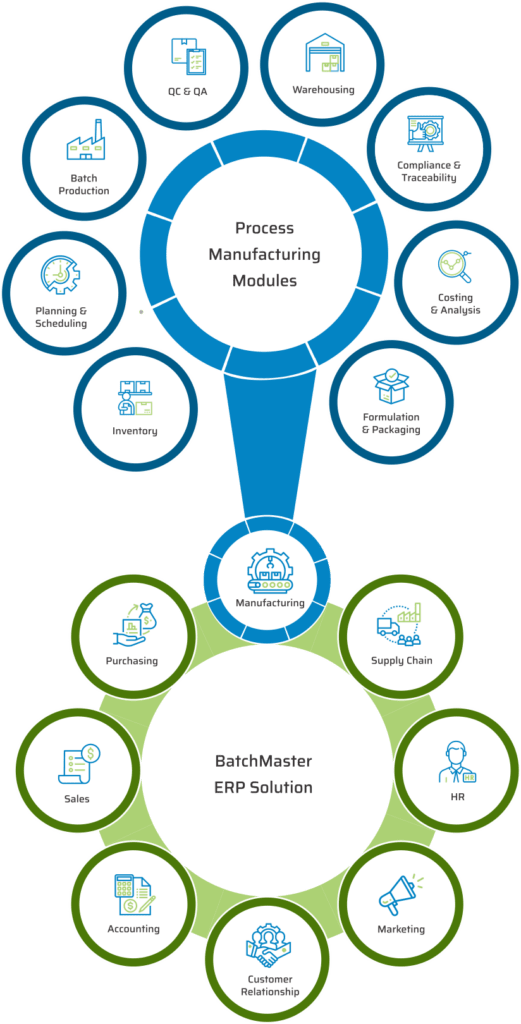

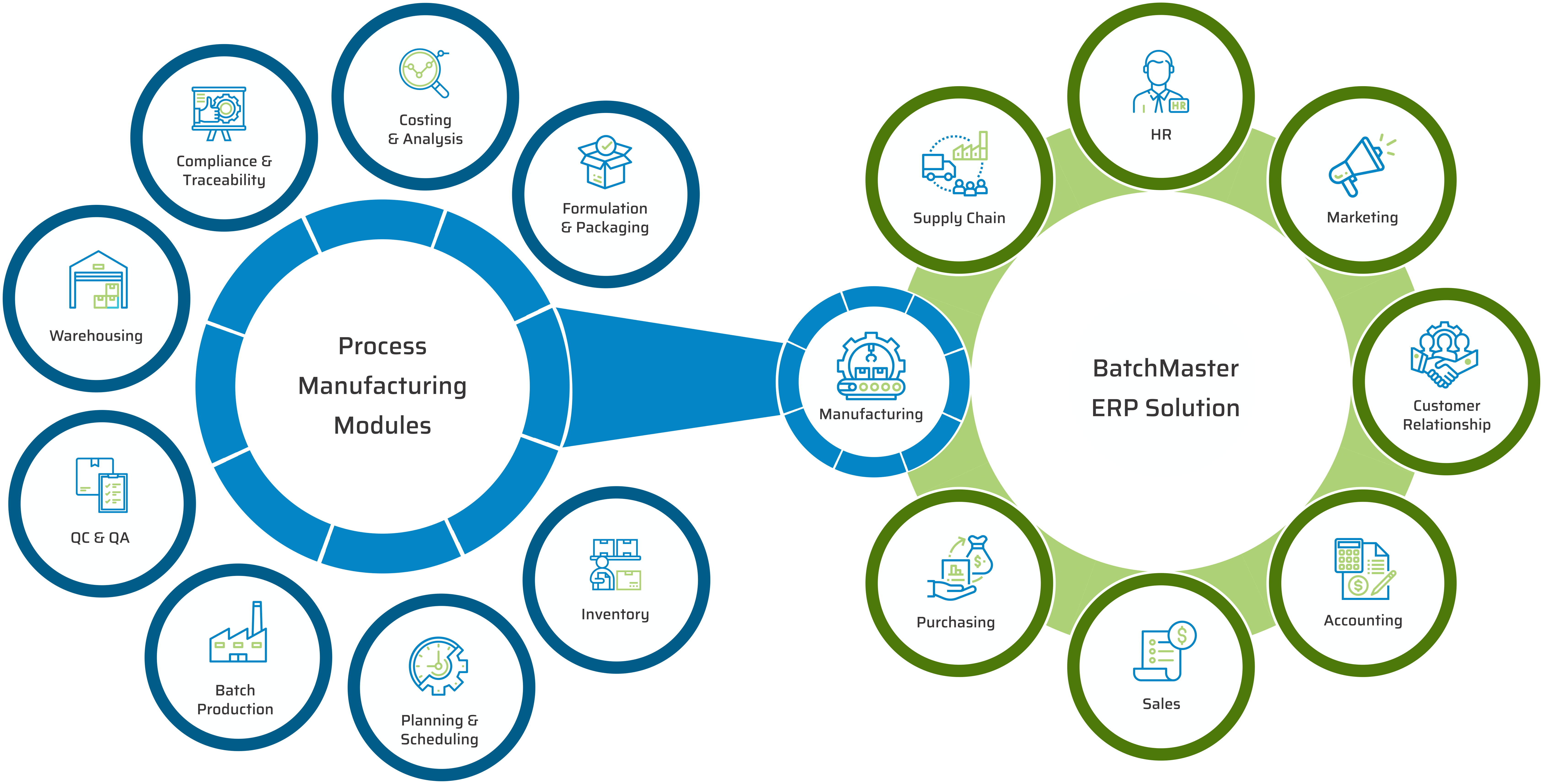

Run A Complete Process Manufacturing ERP System

The #1 ERP and digital core platform for small and midsized businesses, trusted by 60,000+ companies in 150 countries

A leading software vendor of advanced chemical manufacturing software modules

Complete Chemical ERP Solution

SOFTWARE APPLICATIONS FOCUSED ON CRITICAL CHEMICAL MANUFACTURING CAPABILITIES

HELPING YOU MAINTAIN OUR LIFESTYLES AND SURROUNDINGS

UPGRADE TO BATCHMASTER ERP FOR YOUR INDUSTRY

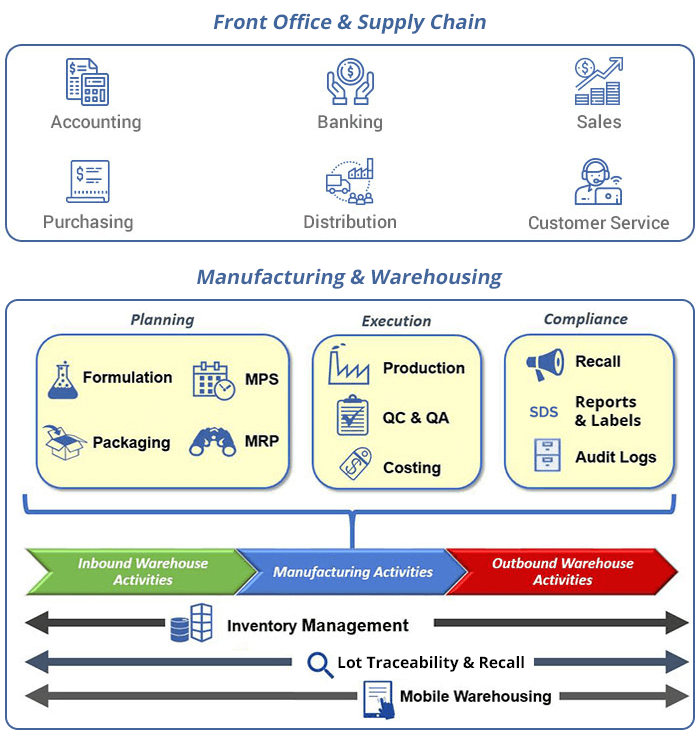

BatchMaster ERP is the enterprise resource planning system designed to meet all of your critical business needs within a single, cohesive platform.

BatchMaster ‘s best-in-class business and industry capabilities for manufacturing and distribution have been natively embedded into SAP Business One, SAP’s market-leading and future-proof platform for small and midsize enterprises

TAKE ADVANTAGE OF LEADING EDGE TECHNOLOGIES

solutions that suit your specific needs.

Cloud

Deploy BatchMaster in the cloud to recognize quicker time to value and a lower cost of ownership. Take advantage of our 'Private Cloud' environment.

Mobile

Manage your business from anywhere, at any time, on any device. Execute and validate warehousing and production tasks on the plant floor

On-Premise

Deploy BatchMaster on your local server. Let our technical staff help your IT staff ensure the system will support your anticipated growth

WHAT OUR CUSTOMERS SAY

About Us

BatchMaster Software is a leading provider of nutraceutical manufacturing ERP solutions that help companies worldwide meet their corporate objectives.

More than

2,000

Happy Customers

More than

2,500

Implementations

More than

40,000

Users

More than

30

Years of Experience

More than

500

Employees

More than

7

Offices

more than

40,000

Users

more than

30

Years of Experience