Manufacturing ERP vs. Industry-specific ERP

A Comprehensive Guide for Manufacturers

What is ERP?

ERP systems, also known as the central nervous system of the business, integrate and automate the core business processes, which include finance, HR, inventory, procurement, and more. An ERP system collects transactional data from multiple sources and promotes data integrity while ensuring a single source of truth.

What are the benefits of choosing the right ERP system?

Businesses need software to improve performance, enhance the bottom line, and offer greater insight for profitable growth. Whether you plan to evaluate an ERP system for the first time or upgrade an existing system, it is very important to understand the features and modules your business needs and consider the cost and implementation model (cloud, on-premise or hybrid).

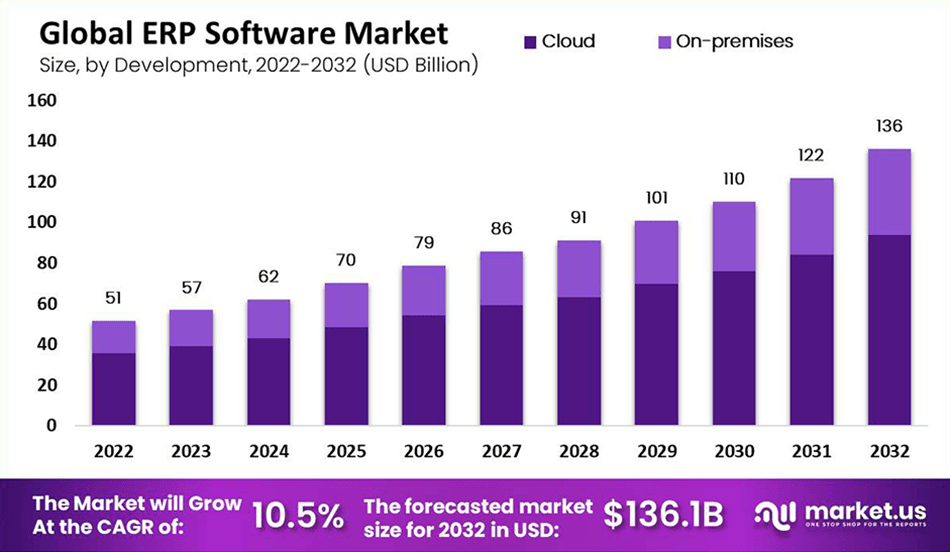

Did you know that the ERP Software Market is expected to be worth $300 billion, by 2027 with a CAGR of 11.9%.

This growth highlights the increasing importance of ERP systems for businesses.

Did you know that the ERP Software Market is expected to be worth $300 billion, by 2027 with a CAGR of 11.9%.

This growth highlights the increasing importance of ERP systems for businesses.

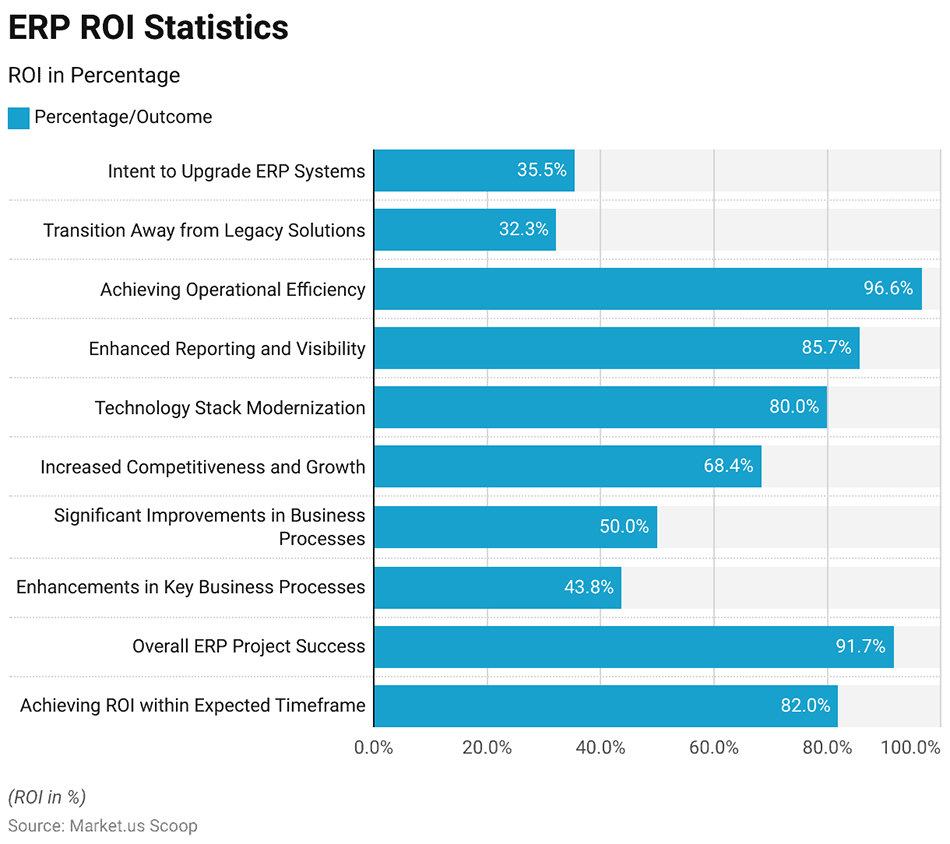

Selecting the right ERP can help organizations in multiple ways:

- A well-suited ERP solution can streamline manual processes, reduce manual efforts, and increase productivity.

- It provides a unified platform for integrating data and ensuring that everyone has access to the same information.

- Real-time data and insights help organizations make informed decisions and respond to market conditions.

- Access to customer data and order history promotes better customer satisfaction and service.

Choosing the right ERP is crucial for operational excellence and improved business performance. It’s an investment that can yield significant long-term benefits when aligned with the organization’s goals and processes, providing a sense of security and confidence in your decision.

What is manufacturing ERP?

1. Improved efficiency and productivity

Integrating various operations, such as order processing, inventory management, production planning, sales, and more, helps manufacturers minimize redundancy and automate routine tasks. This leads to better workflow and empowers decision-makers to focus on value-added activities instead of day-to-day operations.

2. Enhanced data visibility and reporting

3. Better inventory management

4. Reduced cost

Use case for manufacturing ERP

Before

After

Challenges of manufacturing ERP

Customization

Regulatory compliance

What is industry-specific ERP?

Benefits of industry-specific ERP

Use case for industry-specific ERP

Before

Custom Ingredients Inc. is a privately held company based in California with over ten years of experience serving its customers with products such as confectioneries, coffee, and tea.

After

Challenges of industry-specific ERP

Limited Flexibility

Expensive

Take time to evaluate ERP options

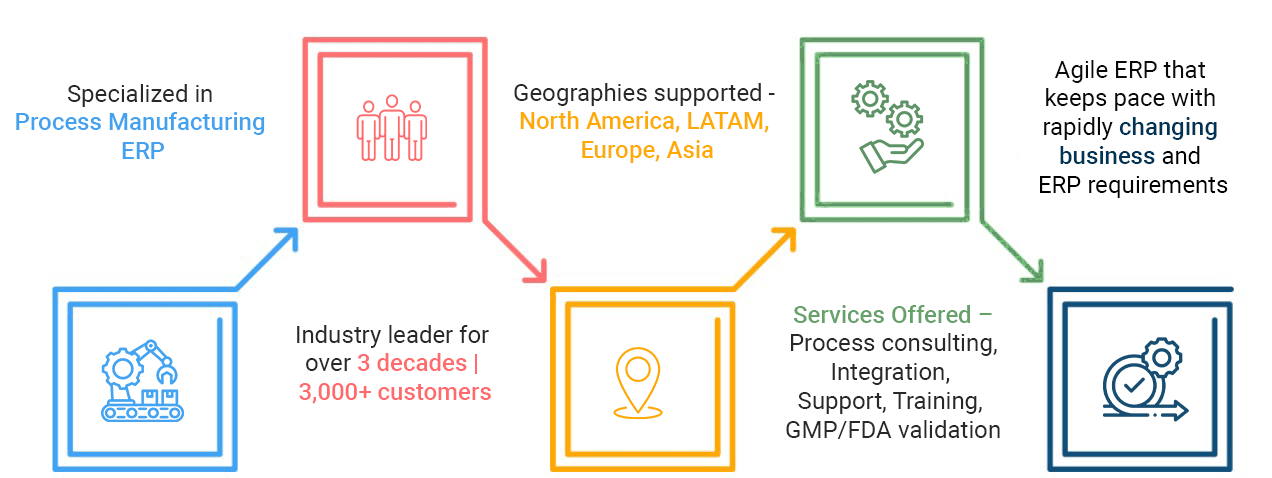

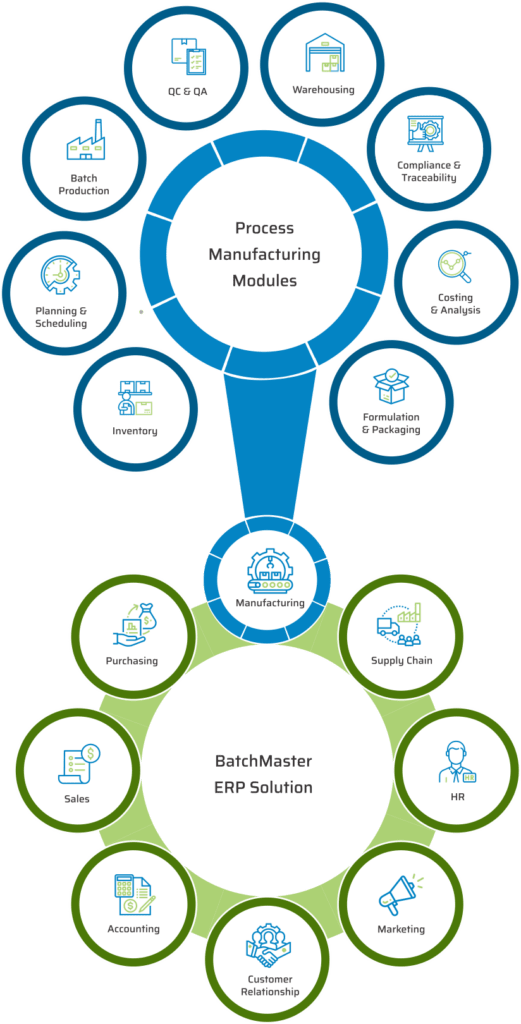

BatchMaster ERP: a leading process manufacturing ERP

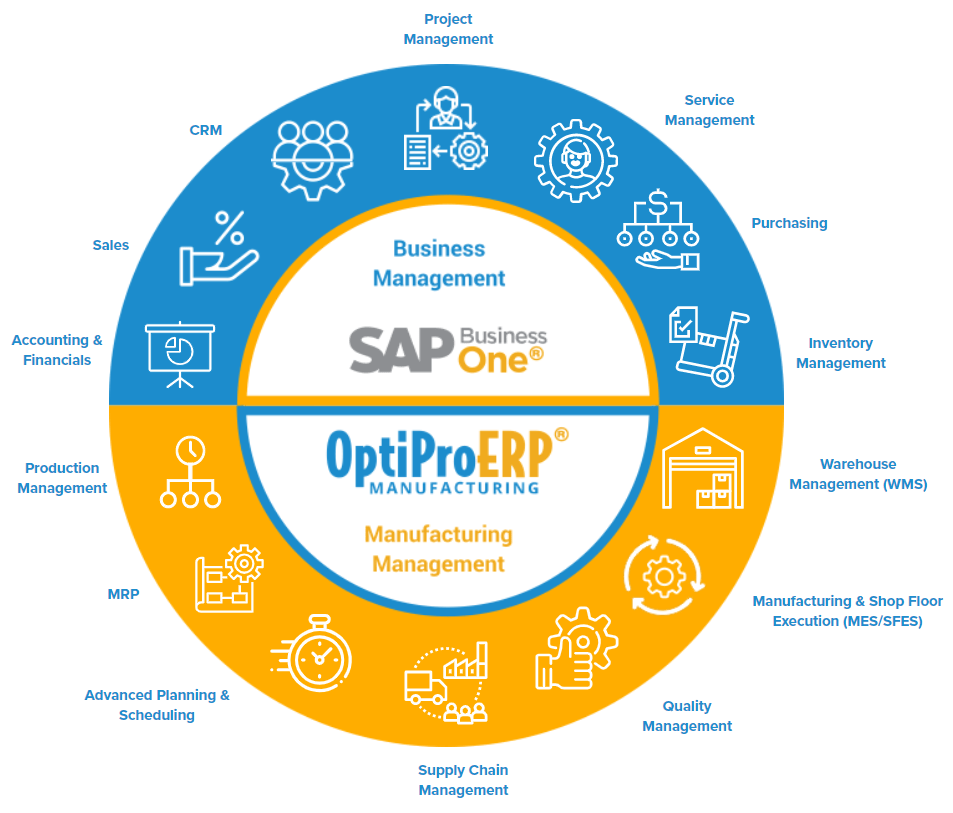

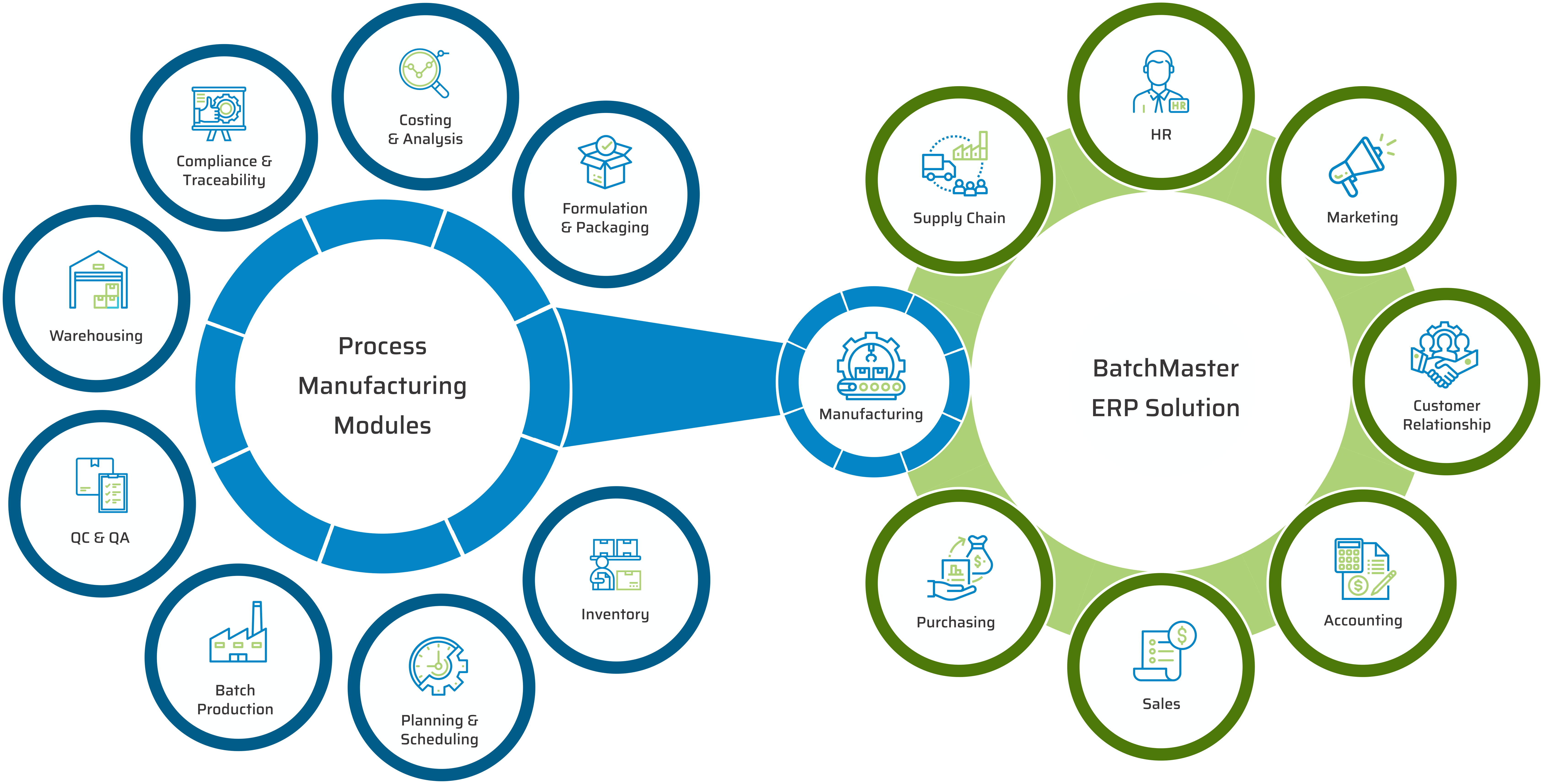

OptiProERP: an industry-specific discrete manufacturing ERP

CRM

Sales

Accounting & Financials

Production Management

MRP

Advanced Planning & Scheduling

Supply Chain Management