As a food manufacturer, your customers probably expect, no demand, the consistent delivery of high-quality products from your company. No customer wants your products to result in any adverse events or consumer complaints, which could potentially lead to product recalls, fines and ultimately, loss of sales.

One of the increasingly-common ways that food processors are being tested for brand protection is through food safety audits and mock recalls by their forward-thinking customers. Many processors that deliver their products to national retail chains conduct mock recalls on a quarterly basis at the behest of the retailers. Many leading processors conduct annual mock-recalls as part of their internal QA procedures. Comprehensive food safety programs have external regulatory or audit agencies validate the mock recall procedures.

So, are you searching for food manufacturing software that supports food traceability capabilities to ensure regulatory and customer compliance? Or just looking to add some level of automated food compliance software or food traceability software to your existing business system?

Being able to quickly and accurately perform product searches requires comprehensive lot management, specifically the mandated capture or auto generation, validation and tracking of lot numbers throughout the product lifecycle. Lot inheritance maintains the lineage of all raw materials and finished products, including co-products and by-products, across all inventory activities.

Advanced drill down lot traceability tools allow you not only perform bi-directional searches in minutes, but also monitor inventory levels and drill down into QC tests against delivered, produced and shipping products, helping you to reduce operating costs and improve customer service.

So, is a food traceability solution more than an insurance policy?

All parties would like to minimize the scope of a recall. Being able to pinpoint supplier ingredients or shipped finished goods enables you to limit the scope of product recalls, saving on-hand inventory and shipped product from being scrapped and avoiding unnecessary actions on the part of your suppliers and customers. The result, lower direct and indirect costs for all parties involved.

Today, brand protection is increasingly being used as a competitive measure. A food processor who can demonstrate the most reliable means of brand protection can have a significant competitive advantage. In some cases, these food processors can command higher prices and enjoy “preferred supplier” status with their customers.

A customer may switch to another supplier based on the failure of even one mock recall. For food processors, the risk of losing a customer due to a failed mock recall is most pronounced when the customer’s investment in brand value is highest. For instance, for a private label food manufacturer that supplies products to national brand marketers, a failed mock recall can be disastrous. As the private label industry grows, food manufacturers will come under increasing scrutiny as the brand retailers seek to reduce their risks. Those manufacturers who cannot conduct fast and accurate mock recalls may be challenged to grow their business.

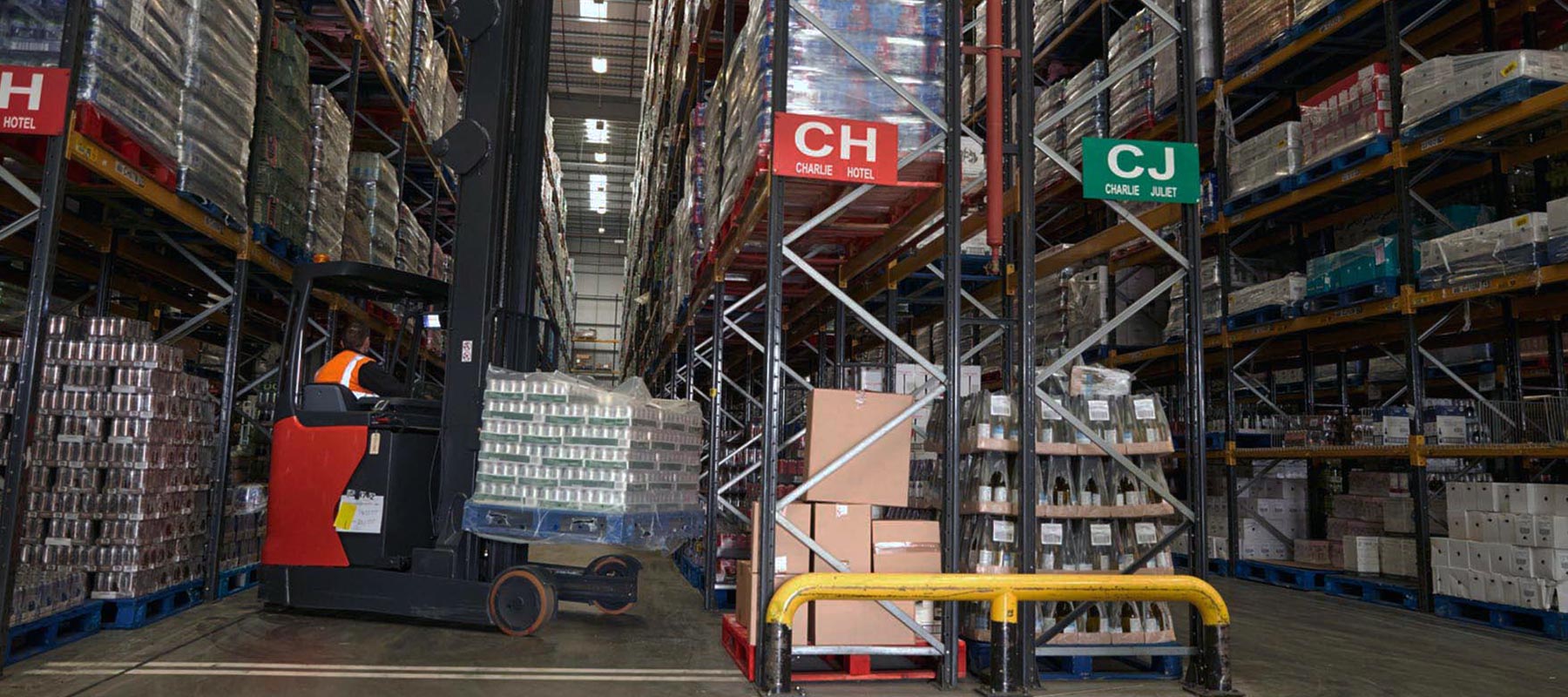

Based upon customer feedback employing our food manufacturing software with its food lot traceability features, it’s clear that demonstrating one’s ability to perform traceability searches or mock recall in minutes, rather than in hours, can facilitate new business contracts with new clients and retain ones with old clients. Having a graphical lot traceability tool at your disposal, it is easy to demonstrate to your business partners and auditors that your company is “in control” of its manufacturing and warehousing operations.

Net net, employing the right traceability software for food manufacturing serves as both a great insurance policy and a great profit generating tool for your growing company.

Associated Link: Speed Lot Traceability & Recall