Polytex Environmental (Netherlands) Inks Finds Holistic Process Solution with BatchMaster Manufacturing (BMM) and SAP Business One

Polytex Environmental Inks, ltd. was established in 1943 by Joseph Landau to manufacture and supply industrial coatings.

Growing concern over air quality in the late 1960s made industries turn their attention to new technologies. The passage of the Clean Air Act in the U.S. in 1970 accelerated the need to develop ink sand coatings that comply with changing environmental standards.

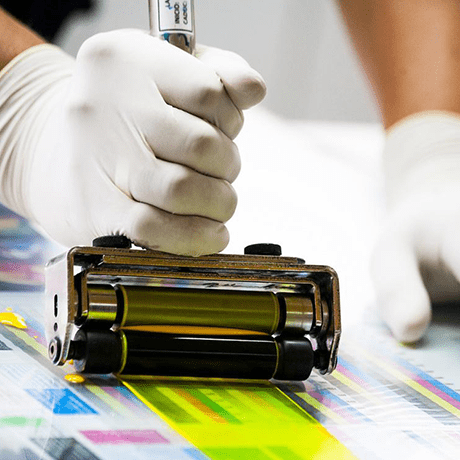

Environmental Concerns became a worldwide issue. Recognizing the evolving need for high performance compliant products Polytex committed its technical resources to developing replacement products for printing and conversion processes.

To effectively support the printing industry, an 80,000 square-foot plant, including research and development and manufacturing, was established in 1986 in the Bronx, N.Y.

To strengthen its position worldwide, Polytex Environmental Inks established an R&D and Manufacturing site in the Netherlands in 1993 to provide local technical and service support for Europe. In 2008, the European arm of the organization began a search for a solution that would support not only the manufacturing and distribution of its products but also full support for its R&D needs.

After some initial research, Polytex identified solutions from Microsoft, Infor Global Solutions, and SAP that offered support for some or most of their business needs. Unfortunately, none of them fully met their needs for product development, production management, and distribution. C.O.O. Henri Pigmans explains their selection process as “extensive… We identified some solutions that were nice looking but seemed cumbersome to implement.”

When the company determined that no solution offered everything they needed, they learned of BatchMaster Manufacturing, an important component of the SAP Business One Partner Solution Suite.

Established in the 1980s, BatchMaster ERP is the original process manufacturing and formula-based product development solution in the software industry.

Early on, SAP identified BatchMaster as a key partner in the service of the process manufacturing industry. BatchMaster responded to their interest by developing the same functionality they offer in their stand-alone ERP package, integrated into the Business One solution. All the technical sophistication of Lot Tracking, Formula Development, and Product Costing available in BatchMaster ERP are now available within SAP Business One, where previously this functionality did not exist.

Before the change, Polytex utilized technology that offered functionality in finance and distribution but with no connection to Lab (Product Development) and Factory (Production Management). According to C.O.O. Henri Pigmans, “We needed a solution that offered us a streamlined process between research and development, manufacturing, and product distribution. We saw a lot of software in our search, but most of what we saw was incomplete for our needs and very expensive to implement.” Pigmans says, “Once we saw the smooth functionality with BMM supporting our process needs, we realized it looked like the right solution. The price met the size of our company as well.”

While SAP Business One was an early favorite for its slick reporting and data mining capabilities, Polytex’s need for support in the lab and on the manufacturing floor drove them to search for alternate solutions. “At first, we didn’t know that a process manufacturing-specific add-on to Business One was available,” says Pigmans. “Once we saw BMM integrated directly into SAP Business One, we knew that we were looking at the right product. We like the way documents come out in a uniform way and appreciate the very organized and professional look that the solution offers.”

Pigmans also points out that their business model makes them unique and that BatchMaster understood and supported their business logic. “Much of what we do is one-off custom,” says Pigmans. “We take existing formulas from stock and customize them to meet the target goals for product application. We make relatively expensive products and pride ourselves on our quick turn-around and responsiveness to our customers.” Pigmans goes on to explain that “product can look different every time. We need to be able to plan our bases but reformulate with almost every order. We may need to replace the components with every sale, but the base remains constant. It’s the finished formula that changes by request. BatchMaster understood those requirements. BMM seems to think the same way we do.”

About BatchMaster Software

BatchMaster Software is a leading provider of ERP solutions that help emerging and growing formula-based manufacturers streamline their operations and scale production while reducing costs and complying with changing customer demands and ever more stringent regulatory mandates. The company delivers industry-specific solutions for Food, Beverage, Nutraceuticals, Pharmaceuticals, Cosmetics, Chemicals, and other process industries. BatchMaster ERP is seamlessly embedded within SAP Business One, providing a comprehensive process manufacturing solution that is available on-premise and in the cloud. BatchMaster Software has served the process manufacturing market for over 30 years and supports thousands of customers worldwide.

Contact Us

BatchMaster Software | 9861 Irvine Center Drive, Irvine, CA 92618 | 949-583-1646 |

sales@eworkplace.com